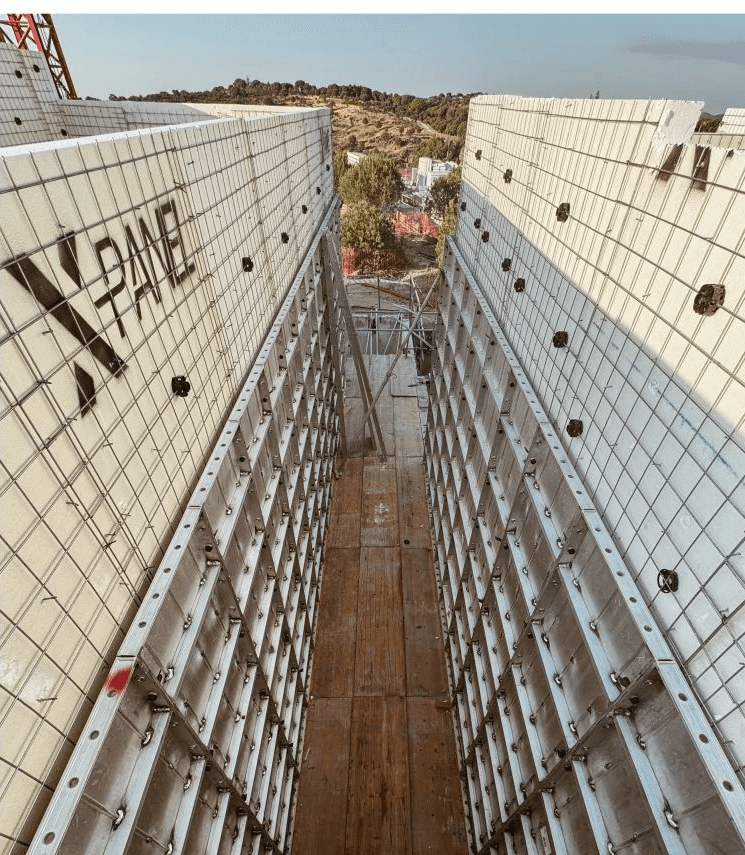

Creating Safer, Smarter, More Productive Construction Sites

We empower businesses with AI-driven inventory solutions that streamline operations, reduce errors, and maximize efficiency.

Our mission to create safer, more productive worksites is guided by four key principles. These values define our technology, our service, and our partnership with you.

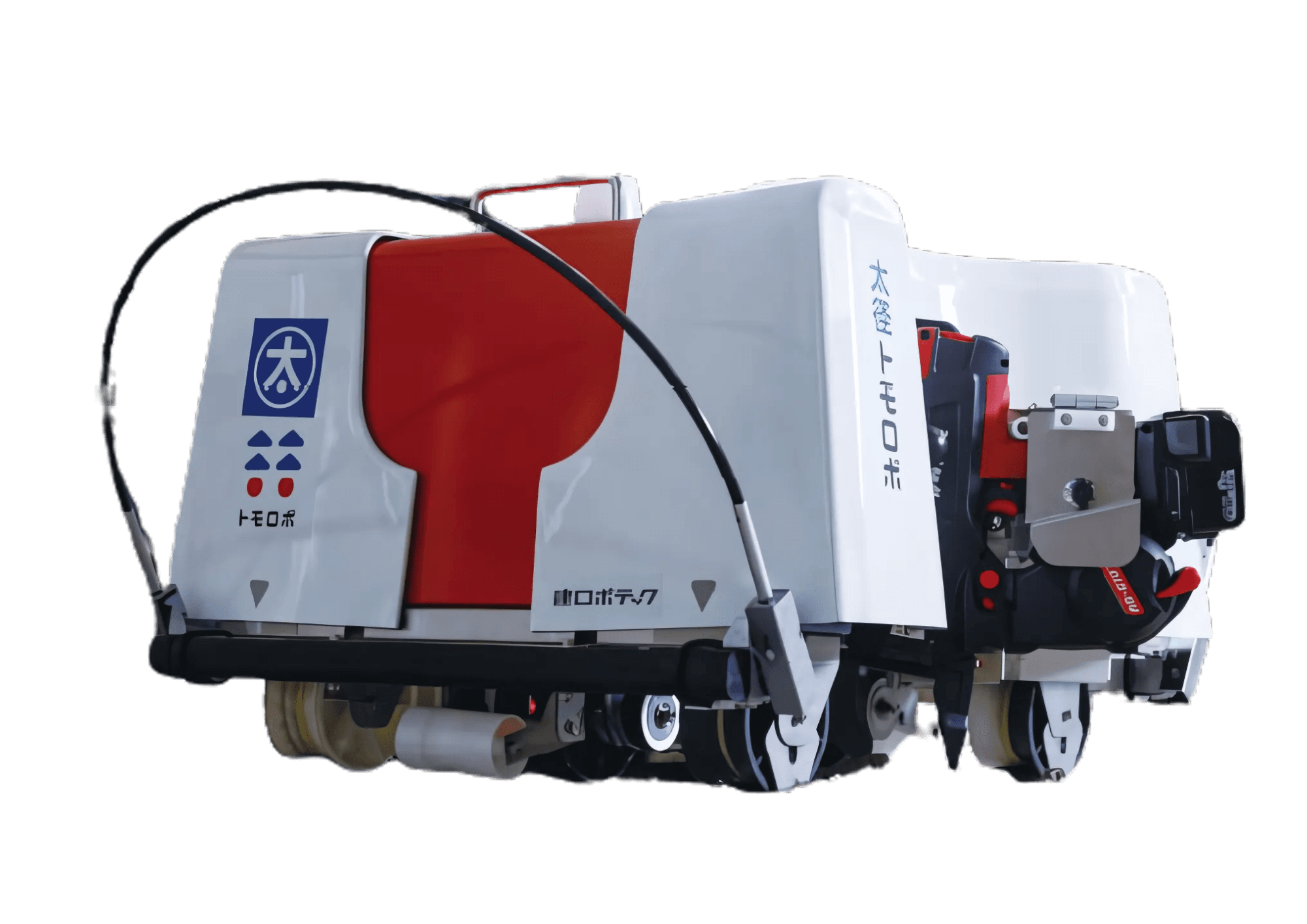

Tomorobo: Automated Rebar Tying

The #1 installed rebar-tying robot in Japan, Tomorobo automates the most physically demanding part of slab preparation. It works up to 1.4 times faster than manual crews , improves site safety by eliminating strenuous, injury-prone tasks , and can reduce direct labor costs by 20-40%. It's the proven solution for faster, more profitable projects.

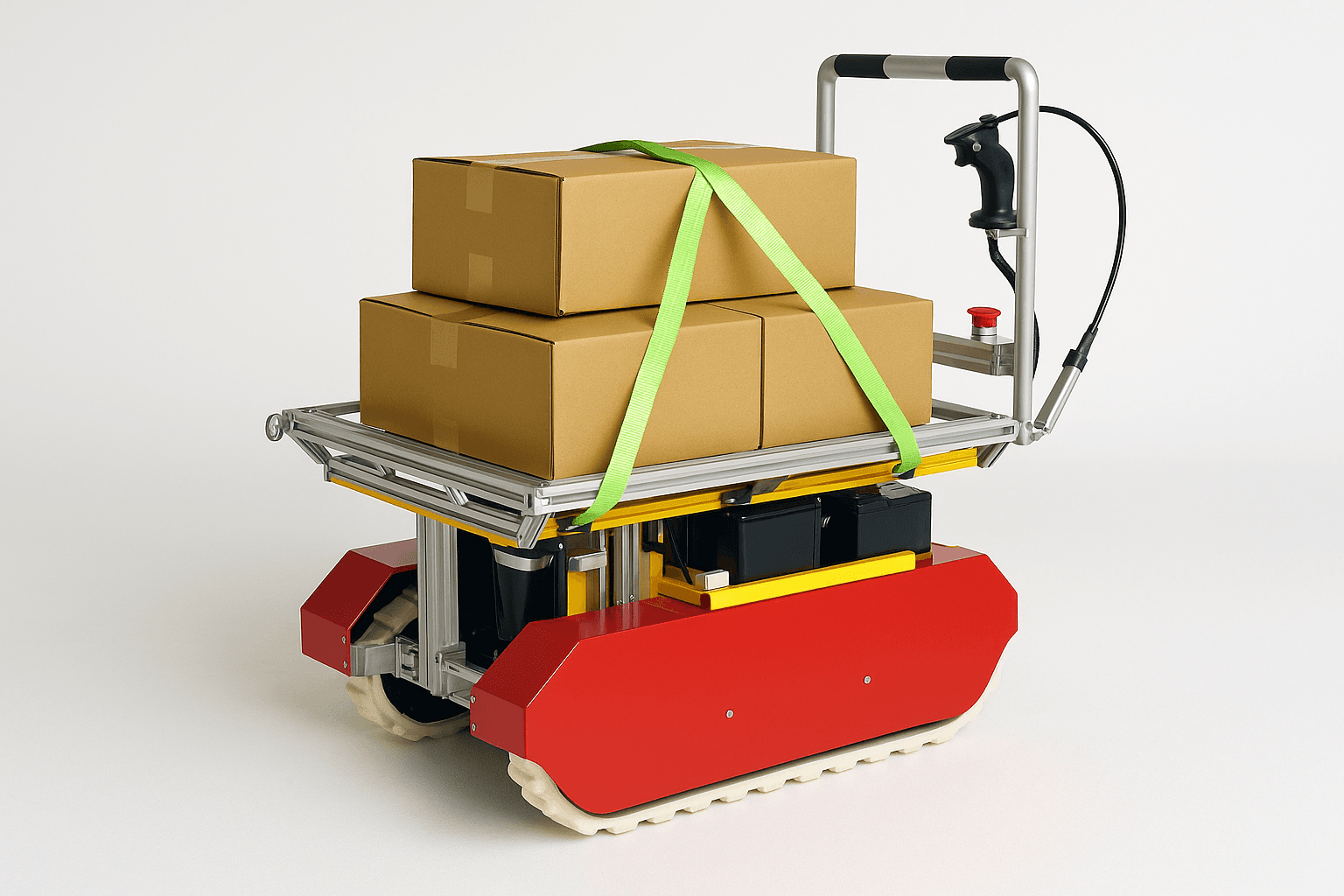

Transport Tomorobo

Transport TOMOROBO is a lightweight, compact robotic solution revolutionizing material handling on construction sites. These COBOTs transport up to 500kg of building materials over rough terrain using temporary rails , enhancing productivity and safety by automating heavy-duty tasks across diverse landscapes.

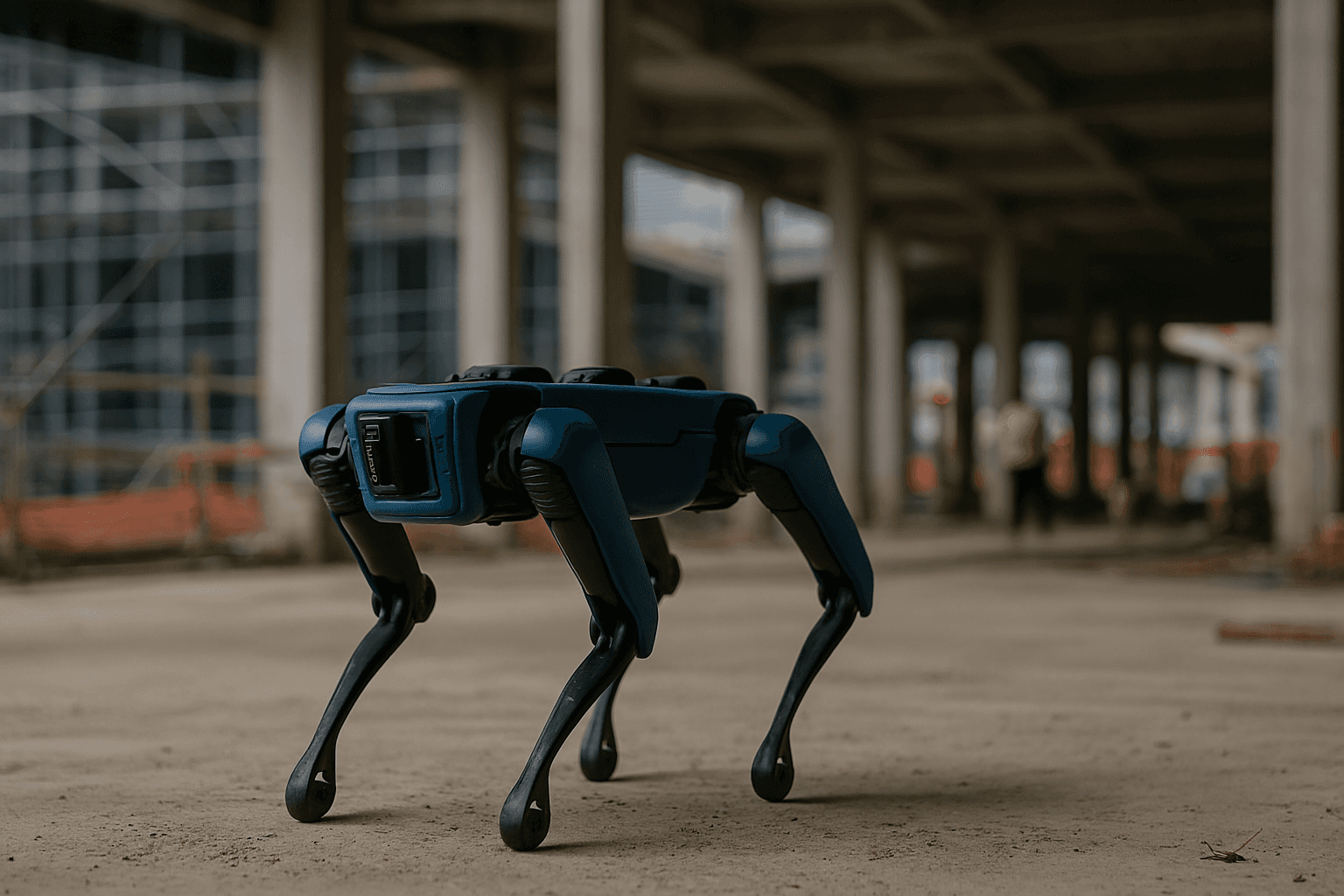

Tomorobo Dog

TOMOROBO DOG is a versatile crawler-type robot designed for human-friendly construction worksites. It effortlessly follows a specific person , avoiding obstacles and stopping when necessary , making heavy material transport easy. With a 150kg load capacity and robust safety features , its customizable platform adapts to various site needs, navigating slopes up to 30 degrees

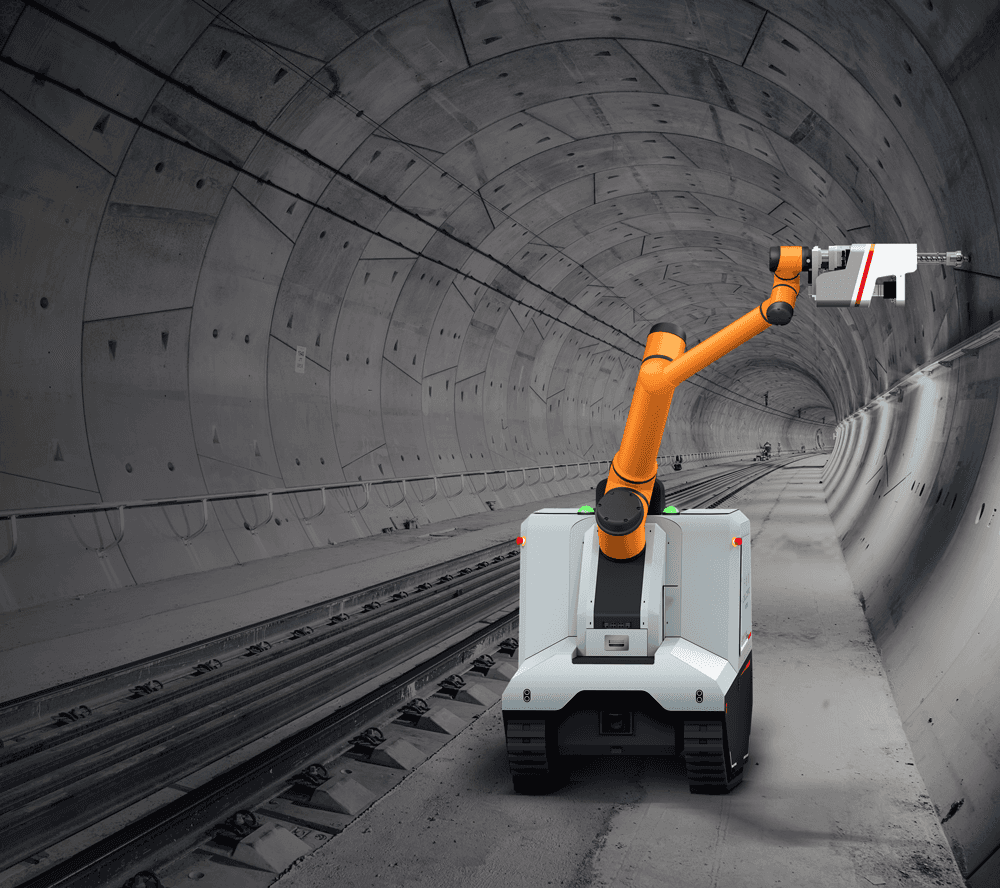

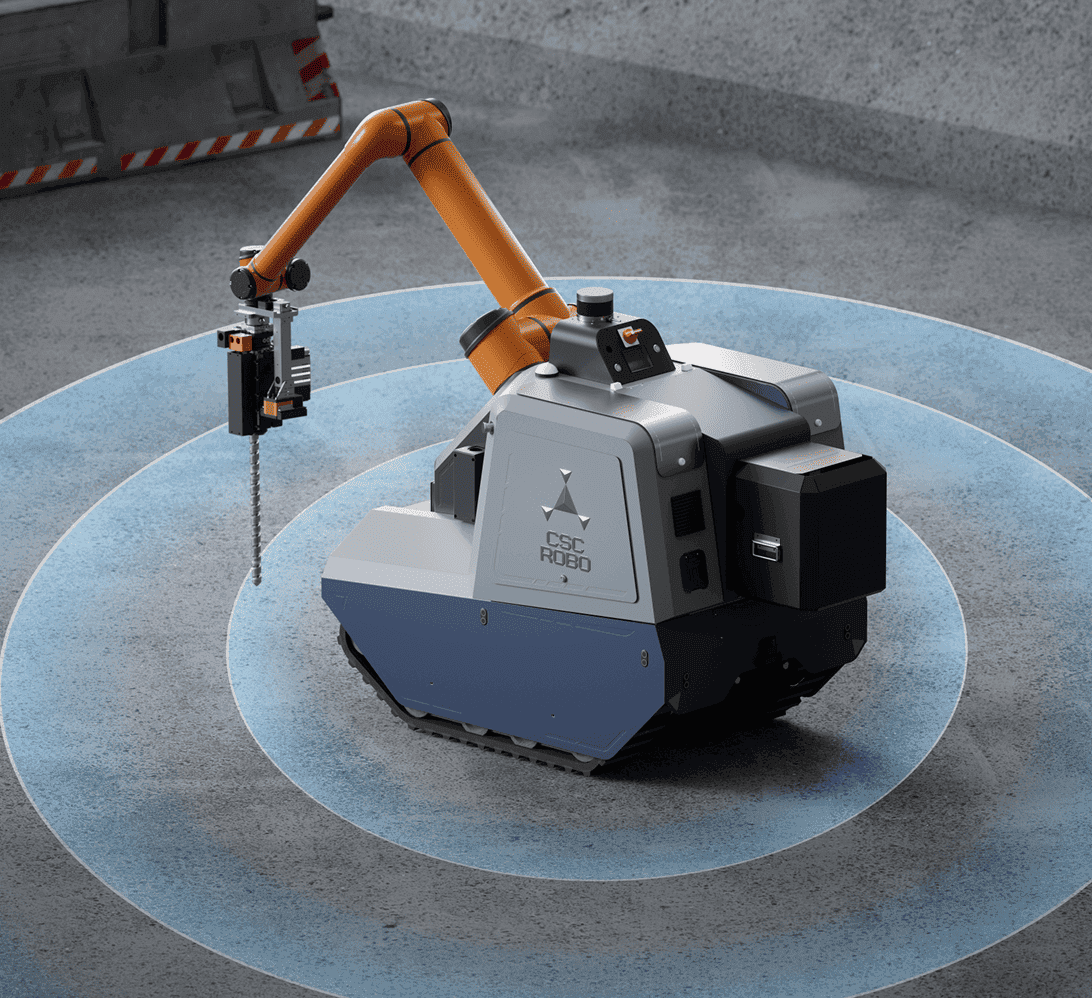

DrillCorpio

Drillcorpio (D3) is an automatic drilling and anchor installation robot for both wall and ceiling. Equipped with a dust vacuuming system, it can simultaneously drill holes and clean up dust, minimizing the need for post-work cleanup and improving efficiency. It is compatible with various construction projects, and can eliminate the need for platform modifications.

Drillcorpio (Model Df)

Drillcorpio (Model Df) is a self-navigating drilling robot. With its advanced capabilities, Df is capable of performing drilling tasks on various surfaces including ceilings, floors and walls. It can drill holes autonomously according to the drilling plan imported from layout drawings. With the auto-navigation technology, Df can move autonomously throughout the work area, dynamically adjusting its path to avoid obstacles and ensure safety. Model Df is suitable for both E&M installations as well as civil works.

The Critical Challenges of Modern Construction

Australian construction firms are under growing pressure. Continuing to use traditional methods for automatable tasks means they are missing out on significant improvements in cost, speed, and safety.

Solution Spotlight: Rebar Tying TOMOROBO

As the first solution in our RaaS lineup, Tomorobo—developed by global construction robotics leader Ken Robotech—directly tackles the costly and labor-intensive task of rebar tying. It works tirelessly alongside your crew to deliver immediate benefits.